How to Inspect Your Existing Home Wiring Before EV Charger Installation

Adding a dedicated home charging station offers convenience, speed, and confidence that your vehicle will be ready for daily use.

With the rapid growth of electric vehicles (EVs), more homeowners across the United States are installing EV chargers in their garages or driveways. Adding a dedicated home charging station offers convenience, speed, and confidence that your vehicle will be ready for daily use. However, before the installation process begins, a critical step is often overlooked: inspecting the home’s existing electrical wiring to ensure it can handle the increased load.

As a professional in the electrical industry, I want to stress that evaluating your home wiring is not a DIY task. It requires technical knowledge, proper testing equipment, and compliance with safety codes set by the National Electrical Code (NEC) and local municipalities. This guide explains the process of inspecting home wiring before EV charger installation, what professionals look for, and why this step matters to safety and performance. By the end, you’ll understand exactly why a professional inspection is essential, what it includes, and how it prepares your home for the future of electric vehicle charging.

Why Wiring Inspection Matters Before EV Charger Installation

Installing an EV charger requires significantly more power than most household appliances. Depending on the charger level, the amperage demand ranges from 12 amps with a Level 1 charger to 40–60 amps or more with a Level 2 unit. If your wiring and electrical panel are outdated or undersized, plugging in a new charger could overload the system—leading to tripped breakers, overheating wires, or even electrical fires.

A professional wiring inspection ensures:

Your system complies with NEC standards and local codes.

The breaker panel has adequate capacity for the additional load.

Wire sizes (gauges) are appropriate for the amperage draw.

Connections, outlets, and grounding are intact and safe.

Risks of overheating, short circuits, or voltage drops are eliminated.

Simply put, an inspection is about protecting your investment in your EV, your home’s electrical infrastructure, and—most importantly—your family’s safety.

Key Steps in Professional Wiring Inspection

When a licensed electrician evaluates a home for an EV charger installation, the process is thorough and structured. Below are the main steps professionals follow.

Load Capacity Assessment

The first priority is determining whether your home’s electrical service can handle the extra demand of the EV charger. Most American homes are equipped with 100-amp to 200-amp service. An electrician will:

Perform a load calculation, factoring in all major appliances (HVAC, water heaters, ranges, dryers).

Identify the maximum available capacity for your electrical panel.

Verify whether a new dedicated circuit can be safely added.

If the electrical panel is near maximum capacity, a service upgrade may be necessary before installing the charger.

Panel and Circuit Breaker Evaluation

Next, an electrician will examine the main panel and any sub-panels. This step ensures there is not only physical space for a new breaker, but also that the breakers are rated appropriately.

Key considerations include:

Available breaker slots for a new EV-dedicated circuit.

Condition of existing breakers (signs of wear, overheating, or mismatched brands).

Main breaker size to confirm total service rating.

Room for potential upgrades, such as smart load management systems.

A dedicated circuit is mandatory for an EV charger, meaning no other appliances will share the same line.

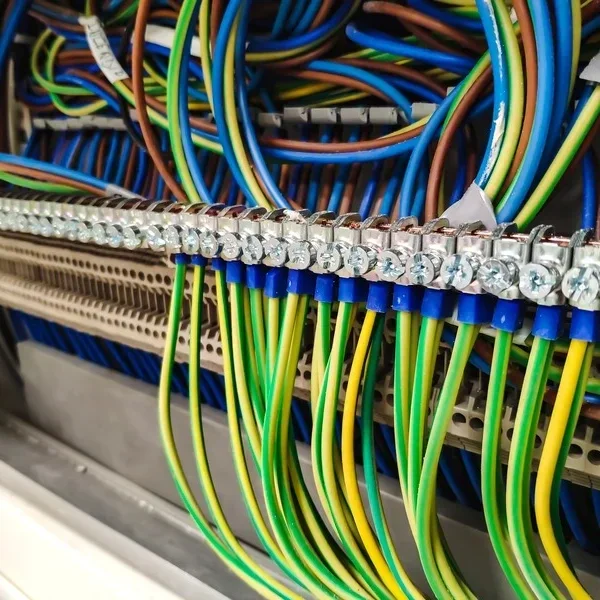

Wiring and Conductor Examination

Wire size and condition play a critical role in safe charging. Professionals inspect:

Wire gauge relative to the charger’s amp rating (e.g., #8 AWG copper for 40 amps).

Wire age and insulation integrity. Older wiring, especially aluminum, may need replacement before use.

Conduit type and protection for wires running across garages, basements, or exterior walls.

Voltage drop testing to ensure efficient charger performance over longer wire runs.

If improper wire sizes or deteriorating conductors are found, rewiring may be necessary to meet code and safety standards.

Grounding and Bonding Verification

Proper grounding ensures safe electricity flow in case of faults. During inspection, electricians confirm:

The home’s ground electrode system is intact and code-compliant.

Bonding between the electrical system and metallic water piping is secure.

That all receptacles, sub-panels, and equipment have proper grounding continuity.

Grounding issues must always be corrected before adding high-demand equipment like EV chargers.

Outlet and Connector Review

If the charger will connect to a NEMA outlet (such as a NEMA 14-50 plug), inspection includes:

Testing outlet stability, polarity, and secure connections.

Checking the amperage ratings of the receptacle and wiring.

Ensuring that only rated outlets are used (commercial-grade where possible).

For hardwired chargers, the electrician inspects wiring routes and termination points instead of an outlet.

Safety Equipment Check

A crucial part of modern installations is verifying that safety devices are in place, such as:

GFCI (Ground Fault Circuit Interrupter) protection for specific outlets.

Arc Fault Circuit Interrupters (AFCI) if required by local code.

Surge protection at the panel to protect both the EV charger and the vehicle.

These safeguards reduce the risks of electrical shocks, arc flash events, and appliance damage.

Common Issues Found During Wiring Inspections

Experienced electricians often come across recurring electrical issues when preparing homes for EV charger installation. Some of the most common include:

Undersized service panels (common in older homes with 100-amp panels, especially when HVAC, cooking, and dryers are already in use).

Old aluminum wiring from the 1960s and 1970s has a higher risk of electrical faults.

Insufficient wire gauge, leading to overheating when subjected to EV charging currents.

Overcrowded conduit runs, which can restrict cooling and damage wire insulation.

Outdated grounding systems, especially in homes built before modern NEC standards.

Shared circuits, where multiple outlets use the same wiring, are prone to overload.

Identifying these problems early prevents dangerous situations and often saves money by integrating corrective work into the installation process.

Preparing Your Home for EV Charger Installation

Once inspection is complete, there are typically three scenarios for homeowners:

Your wiring is in good condition – In this case, installation can proceed with minimal additional work beyond adding a dedicated circuit.

Minor upgrades are needed – Examples may include adding grounding rods, replacing a breaker, or running new conduit.

Major upgrades are required – This could involve a panel replacement, full rewiring of the charger circuit, or a service upgrade to 200 amps.

A qualified electrician will outline these requirements in detail, along with cost estimates and timelines. While upgrades may initially feel like a hurdle, they add long-term safety, ensure compliance, and improve the resale value of the property.

Choosing the Right Professional for the Job

Hiring a licensed and insured electrician is non-negotiable when installing an EV charger in Scottsdale. Look for:

State licensing and proper certifications.

Experience with EV charger installations specifically.

References from other homeowners with successful installations.

Knowledge of regional permitting processes and utility coordination.

Many municipalities require permits and inspections before final approval of EV charger projects. A professional contractor will manage these steps on your behalf.

Benefits of Professional Inspection and Installation

While some homeowners may wonder if they can skip the professional inspection step, the advantages are clear:

Safety assurance – Reduces the risk of fires, shocks, and system failures.

Code compliance – Ensures you meet NEC and local building regulations.

Warranty preservation – Many EV charger manufacturers require professional installation for warranty validity.

Utility incentives – Power companies often offer rebates, but only when licensed contractors perform the work.

Futureproofing – Proper assessment leaves room for future upgrades, such as solar integration or installing multiple chargers.

Instead of viewing inspection as an additional cost, think of it as preventive maintenance and risk management for your electrical system.

FAQs About Inspecting Home Wiring for EV Charger Installation

Do I really need a wiring inspection before installing an EV charger?

Yes. A wiring inspection ensures the home’s electrical system can safely support the added load. Skipping this step can cause overloaded circuits, unsafe conditions, and may void equipment warranties.

How do I know if my electrical panel can support an EV charger?

A licensed electrician will evaluate your main breaker size, review your current electricity usage, and check available breaker slots to confirm if the panel is capable of supporting an EV charger.

Can I install an EV charger on a shared circuit?

No. EV chargers require a dedicated circuit according to electrical code. Sharing a circuit with other appliances increases the risk of overload and potential fire hazards.

What if my home has older wiring, like aluminum?

Aluminum wiring may loosen, creating a fire risk. Most professionals recommend upgrading to copper conductors before installing an EV charger for safer, long-term use.

How much does a wiring inspection cost for EV charger preparation in Scottsdale?

Wiring inspections in Scottsdale generally range from $150 to $400. If upgrades like panel replacement or rewiring are necessary, costs will be higher.

What size wiring is required for a Level 2 EV charger?

Most Level 2 chargers require #8 AWG or #6 AWG copper wiring, depending on the charger’s amperage. The electrician selects the proper gauge to meet both code and manufacturer requirements.

Should I upgrade to a 200-amp service for EV charging?

If your home has 100-amp service and includes other high-demand appliances, upgrading to 200 amps is strongly recommended to support modern electrical loads and EV charging.

Are permits required for EV charger installation in Scottsdale?

Yes. Scottsdale and most surrounding communities require permits for EV charger installation to ensure safety and code compliance. Licensed electricians typically handle the permitting process.

Can I use my dryer or range outlet for charging instead?

No. This approach is unsafe and generally not code-compliant. Only a dedicated circuit designed specifically for EV charging meets safety and legal standards.

Will a home wiring inspection speed up EV charger installation?

Yes. An inspection identifies any necessary upgrades in advance, making installation faster and preventing unexpected delays or costs.

Preparing your home for an EV charger is more than simply mounting a unit on the wall. It involves ensuring your electrical system can safely support the increased demand. A professional wiring inspection is the first and most important step in this process. From verifying load capacity to inspecting conductors and grounding systems, an electrician provides peace of mind that your charging station will operate reliably and safely for years to come.

By investing in a professional inspection, you protect your EV, your home, and most importantly, your family. Whether you’re in a newer suburban development or an older American home, taking the time to thoroughly review your wiring before EV charger installation is the smartest move you can make.